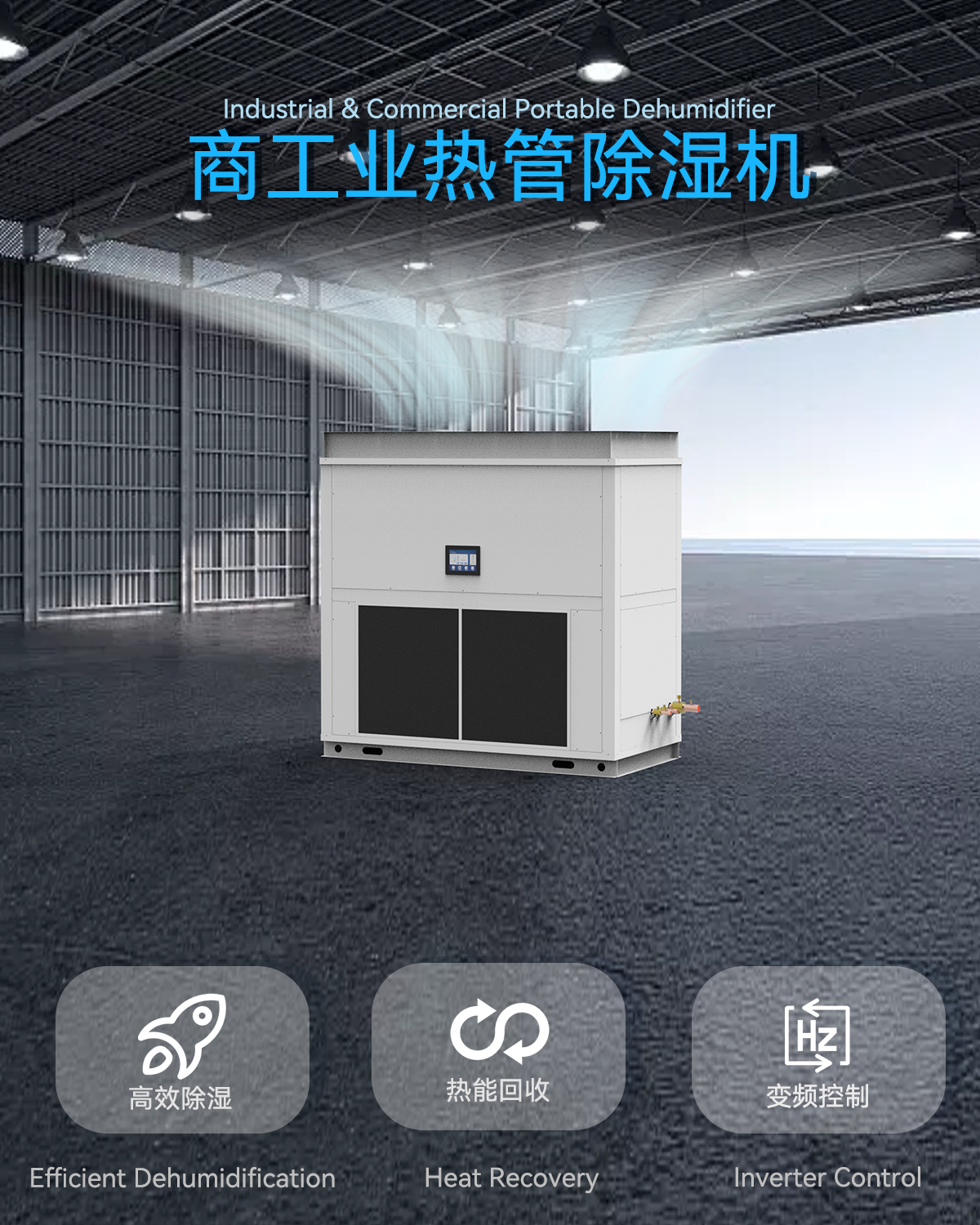

30RT Split-Type Heat Pipe Heat Recovery Dehumidifier

2025-10-29

Supply air at 25°C/28%, easily achieving 35% relative humidity in the space, energy-saving alternative to rotary dehumidifiers. Heat pipe heat recovery dehumidifier; primary filtration; spray cleaning; variable frequency technology. ...

30RT Split-Type Heat Pipe Dehumidifier

· Product Overview

This product is a flagship dehumidification solution that integrates cutting-edge heat pipe technology with industrial-grade high-power design. It is specifically engineered to tackle high humidity load challenges in large commercial and industrial spaces, delivering absolute dehumidification performance while achieving unprecedented energy savings.

Core Design: Heat Pipe Technology × Industrial High Power

The core of this equipment lies in the deep integration of a 25P high-power refrigeration dehumidification system with a high-efficiency heat pipe energy recovery system. Acting as a passive "heat mover," the heat pipe pre-cools the air before it enters the main evaporator, enhancing condensation dehumidification efficiency. Subsequently, it utilizes the recovered heat to reheat the dry, cold air before it is discharged. This process significantly reduces the compressor's load, achieving internal energy recycling.

· Product Technology

-

Heat Recovery

The heat pipe system can effectively recover and reuse the system's own waste heat. Compared to traditional dehumidifiers of the same power, it achieves energy savings of up to 30% - 50%, quickly translating the high initial equipment investment into long-term operational cost advantages. -

Inverter Technology

Inverter technology offers exceptional control over frequency and speed adjustment, enabling more precise temperature and humidity control. The frequent start-stop cycles of fixed-speed technology lead to significant energy consumption. In contrast, inverter technology only needs to adjust the frequency, resulting in greater energy efficiency and higher performance. -

Excellent Temperature and Humidity Control

Powered by advanced algorithms, it provides precise frequency control for different operating conditions. The output air temperature is comfortable, perfectly solving the industry pain point of "getting colder while dehumidifying." It is particularly suitable for locations requiring a constant ambient temperature.

· Application Scenarios

-

Industrial Manufacturing: Large production workshops, food processing plants, pharmaceutical production bases, lithium battery manufacturing drying rooms.

-

Warehousing and Logistics: Large granaries, tobacco warehouses, paper storage warehouses, high-tech product storage centers.

-

Public and Special Projects: Large underground spaces, aquariums, swimming pools, museum archives, drying for large construction sites.

· Product Specifications

Model: HPD-30-1

Airflow: 3000-12000 CMF

Dehumidification Capacity: 30-100 kg/H

Refrigerant: R410A

Compressor: Hitachi

Rated Power: 18 KW