Introduction and Case Sharing of Heat Pipe Heat Recovery Variable Frequency Dehumidifier - Saving Millions in Electricity Costs Annually

2025-12-29

Saving over a million in electricity cos...

Project Introduction

1. Traditional constant temperature and humidity units use chilled water for cooling and dehumidification, and electric heating for reheat to control temperature and humidity, resulting in extremely high energy consumption. The operation of dual-stage water pumps leads to higher maintenance costs in the long run.

2. In this case, the customer reported that the new product requires lower humidity. The old equipment could not achieve 25°C, 35% RH, and had extremely high power consumption and low product yield.

-

-

-

Energy Consumption Comparison

vs Traditional Chilled Water + Electric Heating: Saves 120 kWh/hour

vs High-Energy Consumption Desiccant Wheel Dehumidification: Saves 130 kWh/hour

Integrates multiple heat recovery technologies, drastically reducing energy consumption!

Reduces the probability of casting failure due to excessive mold humidity, greatly improves product yield, increases corporate profits, and lowers overall costs.

| Name | Dehumidification Capacity | Cooling Capacity | Electric Heating | Total Power | Annual Power Consumption (kWh) |

|---|---|---|---|---|---|

| Chilled Water + Electric Reheat | 26 kg/h | 117 kW | 96 kW | 145 kW | 1,270,200 |

| Variable Frequency Cooling + Condenser Heat Recovery | 46 kg/h | 96 kW | 0 | 19.2 kW | 168,192 |

| Variable Frequency Cooling + Cold & Heat Recovery + Condenser Heat Recovery | 46 kg/h | 96 kW | 0 | 11.7 kW | 102,492 |

-

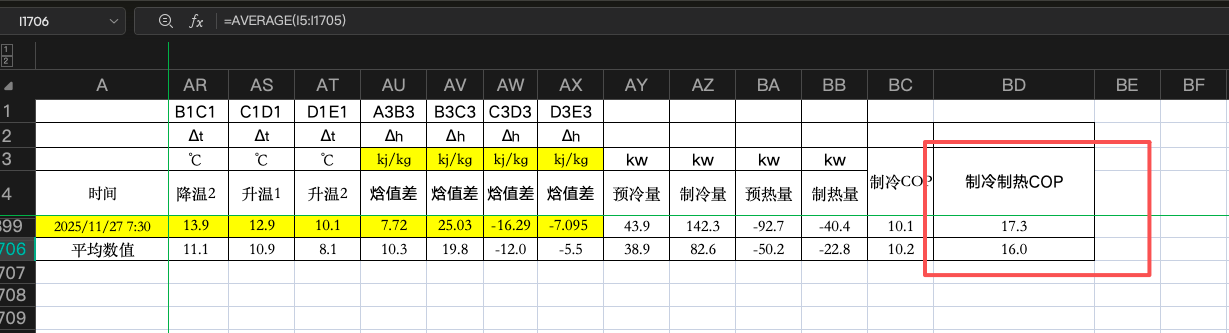

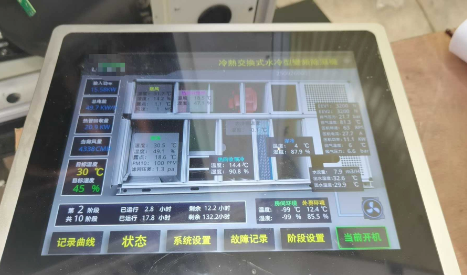

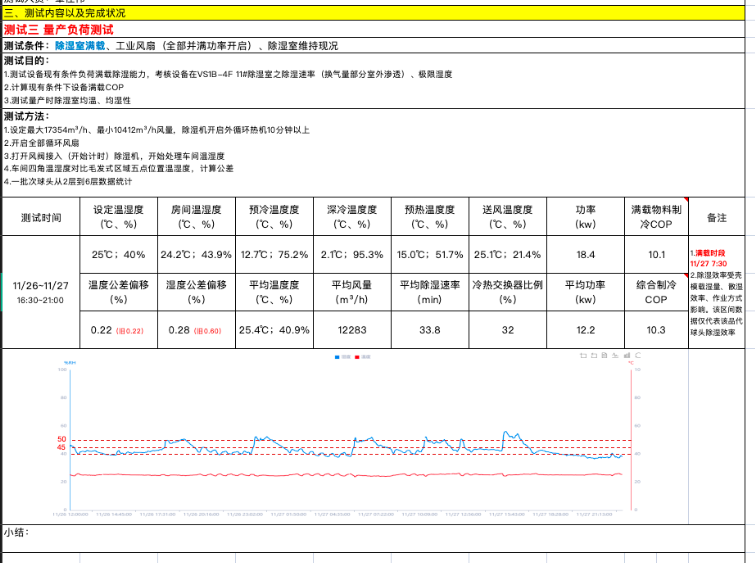

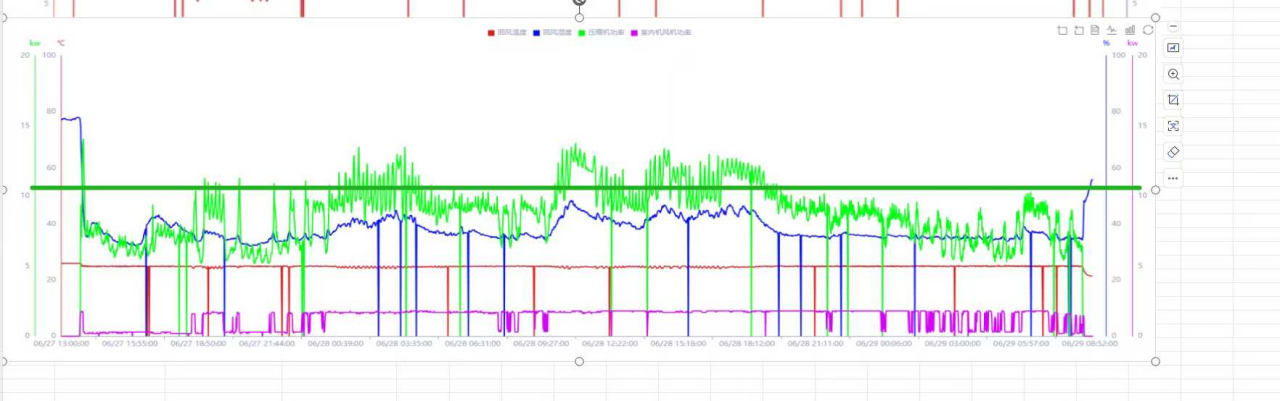

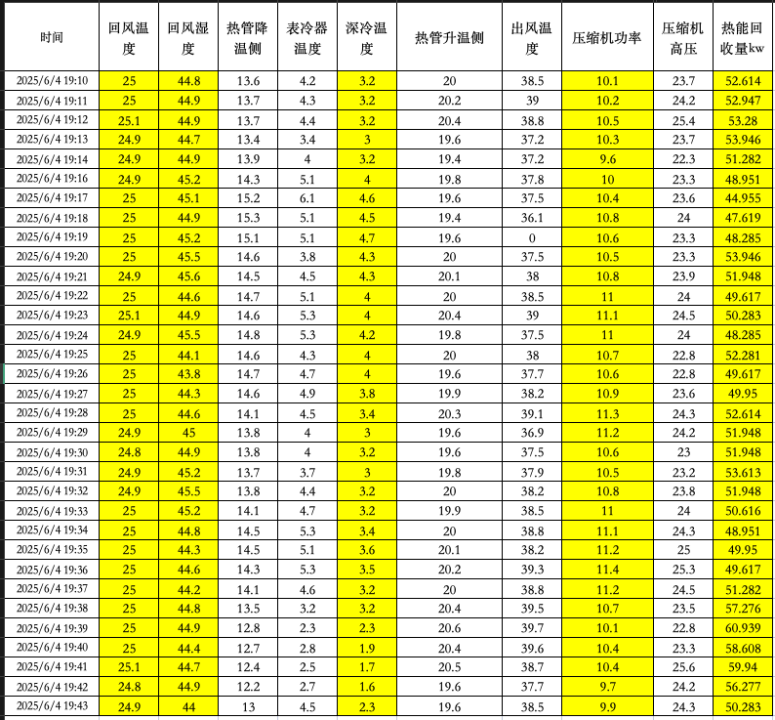

Customer's Actual Measured Data

Main Features

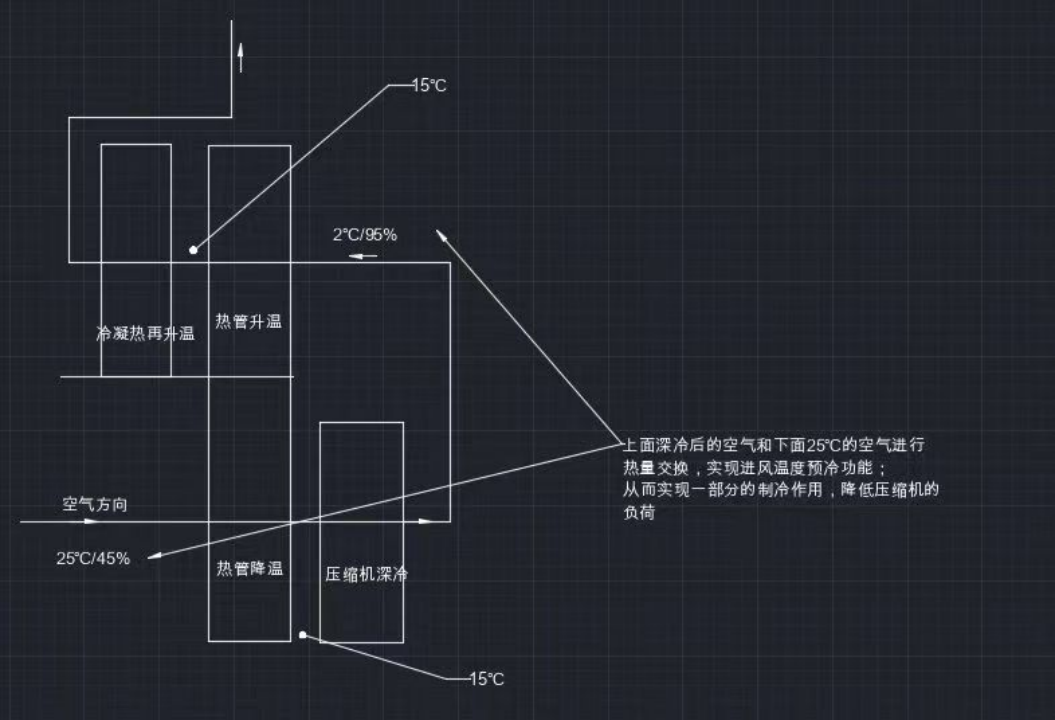

3. Existing case (25°C/45% inlet air condition) recovers 54 kW of cooling capacity per 10,000 air volume.

Remote OTA Upgrade

Case: A customer's equipment required cooling even in winter, with outdoor ambient temperatures below 0°C. After internal communication, we provided a solution immediately and completed the OTA upgrade within 3 hours.

Outstanding Energy Saving

More Energy Efficient: Existing case at full load operation (continuous inlet air 25°C/45%), 10,000 air volume requires only 11 kW compressor running power, dehumidification capacity reaches 30 kg/hour, deep cooling temperature can be maintained at 3.5°C.

Replaces the traditional chilled water + electric heating method (100 kW), saving the customer 70,000 yuan per month (for non-24/7 usage).

Dual electronic expansion valve throttling control + dual oil return design

High-precision control of refrigerant flow, longer compressor lifespan.

More effective and reliable compressor lubrication, longer lifespan.

High-temperature model can achieve 18-85°C supply air temperature.

Cascade system can achieve 18-120°C supply air temperature.

Condenser Heat Recovery (Outlet Air Temperature Can Be Set)

Recovers compressor waste heat for reheating.

Standard model can achieve 18-45°C supply air temperature.

Medium-temperature model can achieve 18-65°C supply air temperature.

Equipment Principle

1. Uses zero-energy-consumption heat pipe heat recovery to pre-cool air to 15°C.

2. Compressor refrigerant deep cooling cools air to 2°C, significantly reducing air moisture content.

3. Zero-energy-consumption heat pipe heat recovery pre-heats air to 15~18°C.

4. Compressor waste heat reheats air to 25~35°C (according to drying room heat demand).

5. No electric heating involved throughout the entire process. Pre-cooling, pre-heating, and reheating are achieved using zero-energy-consumption heat recovery technology.

-

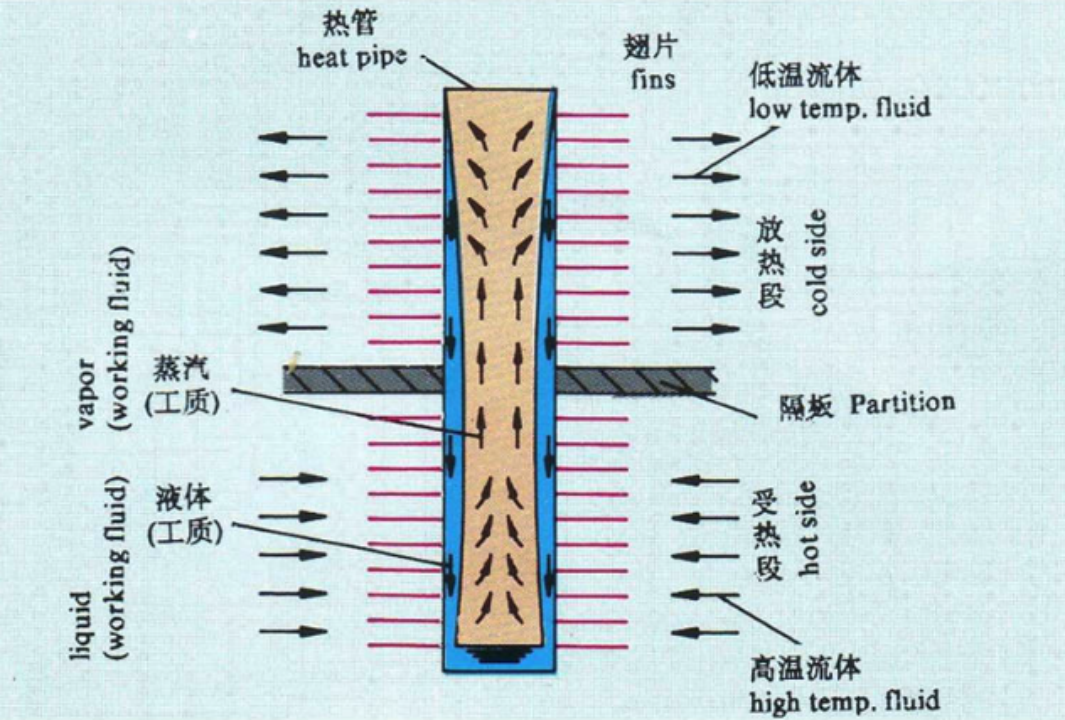

What is a Heat Pipe?

A heat pipe is a heat transfer component with high thermal conductivity. It efficiently transfers heat through the phase change process (evaporation and condensation) of its internal working fluid at the cold and hot ends.Its Main Characteristics

Extremely High Thermal Conductivity: Its heat transfer capability far exceeds that of most solid metals.

Passive Operation: Requires no external power, operates solely on its own physical processes.

Application Fields: Commonly used in areas with extremely high heat dissipation requirements, such as: Semiconductor heat dissipation, Aerospace, High-efficiency energy-saving air conditioning and dehumidification systems, Rapid Thermal Response: Can quickly transfer heat from the heat source to the heat sink.

-

Heat Pipe vs. Common Material Thermal Conductivity Comparison

| Material | Thermal Conductivity W/(m*K) |

| Heat Pipe | 5,000-100,000 |

| Silver | 429 |

| Copper | 401 |

| Aluminum | 273 |

| Pure Iron | 80 |

| Stainless Steel 304 | 14 |

-

Actual Measured Performance, Redefining Energy Efficiency Standards

-

· Cooling COP: 9.5

· Comprehensive COP: 19

We have integrated all cutting-edge energy-saving technologies to reduce your operating costs to unprecedented new lows.

-

Related Images

Product Tags

#CastingTechnology #CastingScience #CastingMachinery #EnergySaving #SustainableDevelopment

-

Keywords

- Precision Casting Process

- Energy-Saving AHU

- Energy-Saving Dehumidifier Temperature Control

- Heat Pipe Technology Application