Case Study: Low Dew Point Variable Frequency Air-Cooled Temperature and Humidity Control, Halving Energy Consumption in Gummy Production Workshop

2025-12-24

To address the high energy consumption f...

Customer Challenges

- Traditional AHUs rely on 7°C chilled water for deep dehumidification, followed by electric reheating, driving multiple high-power pumps, leading to a sharp increase in overall energy consumption.

- Other areas of the plant only require 12°C chilled water, but this temperature cannot meet the dehumidification zone's needs, resulting in wasted cooling capacity and process fluctuations.

- High humidity environments limit gummy drying efficiency, restricting process stability and making it difficult to achieve planned production capacity.

Solution

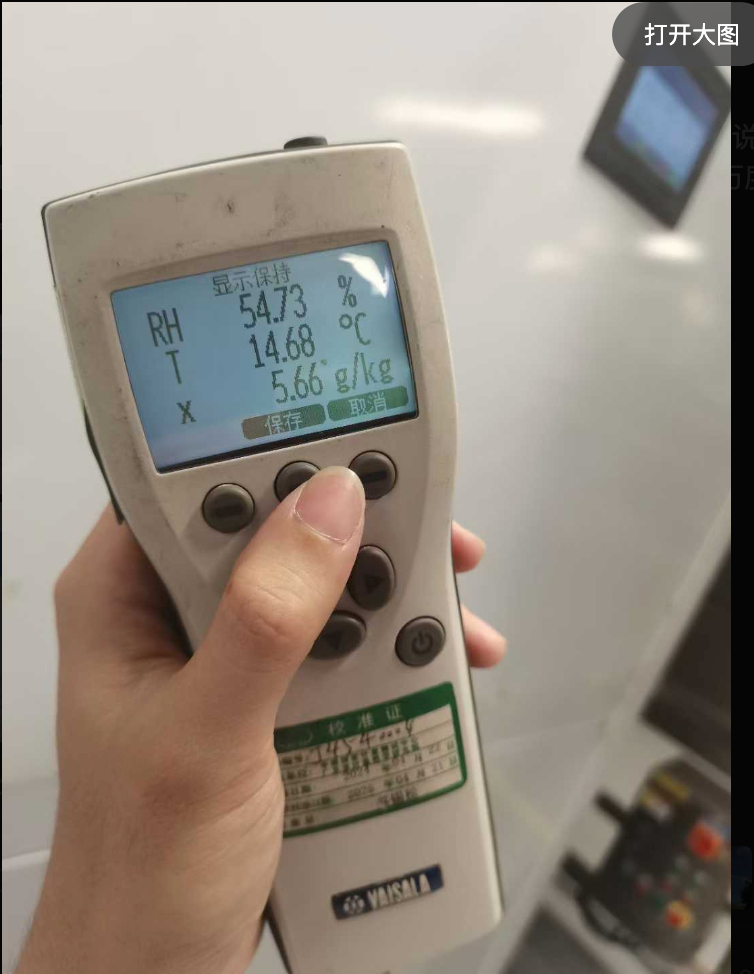

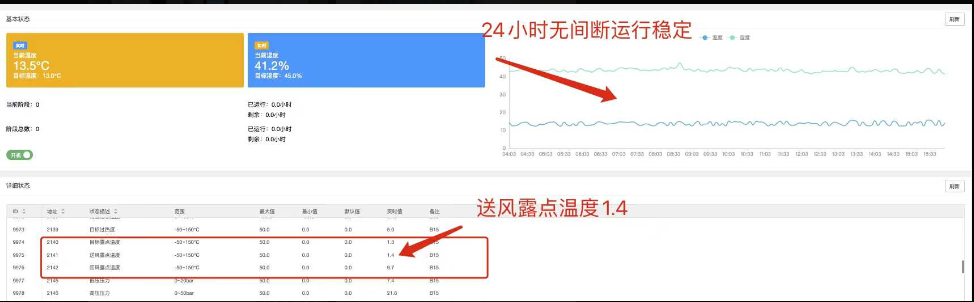

- Equip the gummy production area with a low dew point variable temperature dehumidifier providing 45 kW cooling capacity and 36 kg/h dehumidification, delivering a dew point of 2.5°C and supply air at 35% RH @ 18°C.

- While providing precise humidity control, the equipment also supplies 30 kW of sensible cooling, reducing the original system's reliance on low-temperature chilled water.

- The system is uniformly switched to a 12°C chilled water cycle, reducing pump operation pressure and avoiding additional power consumption from multiple pumps running in parallel.

- The solution meets the environmental requirement of 45% RH @ 25°C while fully replacing desiccant dehumidifiers and chilled water + electric heating combinations, extending to various scenarios such as food plants, pharmaceuticals, dry rooms, and indoor swimming pools.

Quantified Results

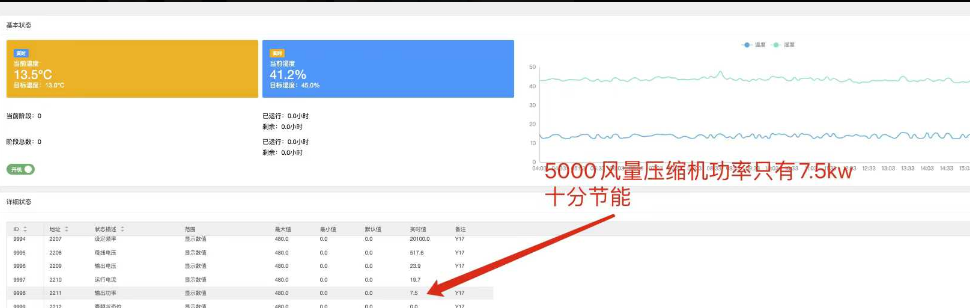

- Cooling/dehumidification power in the dehumidification zone dropped sharply from 100 kW to 8 kW, significantly reducing energy consumption.

- Daily electricity consumption for the entire plant decreased from 20,000 kWh to 10,000 kWh, saving approximately 8,000 yuan per day on average.

- After raising the chilled water temperature to 12°C, the chiller's COP increased by about 10%, curbing carbon emissions and long-term maintenance costs.

- Reduced humidity fluctuations improved both gummy drying time and quality control stability, achieving a higher yield rate.

Related Keywords

- industrial dehumidifiers

- commercial dehumidification systems

- humidity control solutions

- food plant dehumidification

- dry room dehumidifier

- desiccant dehumidification systems

- clean room humidity control